The Habitat

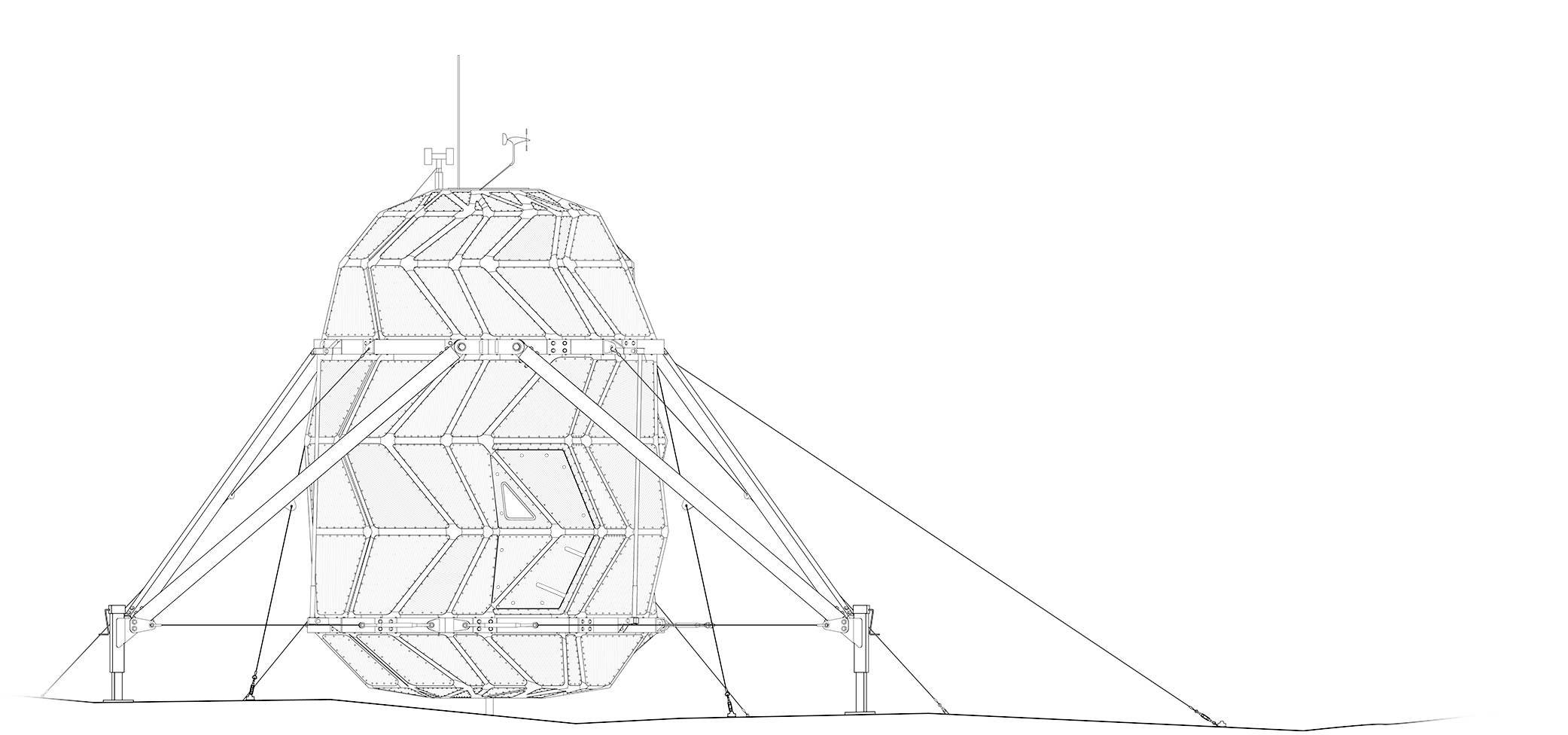

The LUNARK habitat is an example of what happens when the architect steps back and allows the extreme environment on the Moon and the high arctic to mold a habitat around two human beings. Inspired by the patterns seen in a budding leaf as it unfolds, we created an origami habitat which unfolds from a tight bud to a large ovoid shape with a rigid carbon fibre shell. It’s exterior is tough as a tank while its interior is a cozy home with a sense of Nordic “hygge”.

A black glossy shell made of carbon fiber makes out the main exterior of the habitat. The carbon fiber structure is sandwich panels with a foam core for extra insulation. Carbon fiber is ideal because it’s lightweight - which is crucial for transport and unfolding - yet strong. The panels are connected by a white foldable composite rubber. The main load bearing structure is an aluminium frame.

Mark 1

Specs

Folded Storage Volume

2.2m³

Deployed Inner Volume

17.2m³

Volume Increase

750%

Shipping Dimensions

2.23m x 2.23 x 2.23m

Weight

1738kg

Crew Capacity

2 people

Pressurized

No

Min. Temp.

-45°C

Power Source

Solar Panels

Battery Capacity

1000Ah

The Habitat Overview

We put our most innovative designs to the test, to demonstrate how space architecture could look, and accelerate the architecture and technology of future Moon habitats. habitats. These are some of the ideas we tested:

- Dynamic Circadian Light System: Similar to the poles of the Moon, there is near constant sunlight, so we needed to create an artificial circadian rhythm.

- Solar Panel Skin: The exterior of the habitat is covered in solar cells to maximize the energy generation.

- Sleeping Pod: A comfy, private space is key for human well-being in space. A cozy cocoon where you can relax and escape your environment, and keep your personal belongings. Available space is also maximized, by having the sleeping pods above the living quarters.

- Expanding Architecture: Because the habitat had to be transported in a shipping container (and potentially later by a rocket) there is very strict volume requirements.

- 3D printer: A 3D printer is crucial in space. The ability to quickly create any tool you need as the need arises is very handy. It allows flexibility and solutions to problems that may yet be unknown. You also might not know which tools you need at launch, so being able to print only the ones you do end up needing helps save weight during launch.

- Batteries, water tank, storage: Utilization of vertical space is crucial when you do not have much to work with.

- Algae-based life support system: To help with the human longing for nature, an algae reactor brings life into a sterile environment and helps the psychological well-being of crew members with calming, bubbling sounds. The algae can even be harvested as a fresh and healthy source of nutrition to break up an otherwise bland selection of meals.

The Habitat Overview

We put our most innovative designs to the test, to demonstrate how space architecture could look, and accelerate the architecture and technology of future Moon habitats. habitats. These are some of the ideas we tested:

- Dynamic Circadian Light System: Similar to the poles of the Moon, there is near constant sunlight, so we needed to create an artificial circadian rhythm.

- Solar Panel Skin: The exterior of the habitat is covered in solar cells to maximize the energy generation.

- Sleeping Pod: A comfy, private space is key for human well-being in space. A cozy cocoon where you can relax and escape your environment, and keep your personal belongings. Available space is also maximized, by having the sleeping pods above the living quarters.

- Expanding Architecture: Because the habitat had to be transported in a shipping container (and potentially later by a rocket) there is very strict volume requirements.

- 3D printer: A 3D printer is crucial in space. The ability to quickly create any tool you need as the need arises is very handy. It allows flexibility and solutions to problems that may yet be unknown. You also might not know which tools you need at launch, so being able to print only the ones you do end up needing helps save weight during launch.

- Batteries, water tank, storage: Utilization of vertical space is crucial when you do not have much to work with.

- Algae-based life support system: To help with the human longing for nature, an algae reactor brings life into a sterile environment and helps the psychological well-being of crew members with calming, bubbling sounds. The algae can even be harvested as a fresh and healthy source of nutrition to break up an otherwise bland selection of meals.

Closeup of the foldable door, with the only window in the structure, which reveals the warm safe home inside.

Habitat 3D model

Play around with this 3D model of the habitat. You can see the solar panels which almost cover the entirety of the exterior shell.

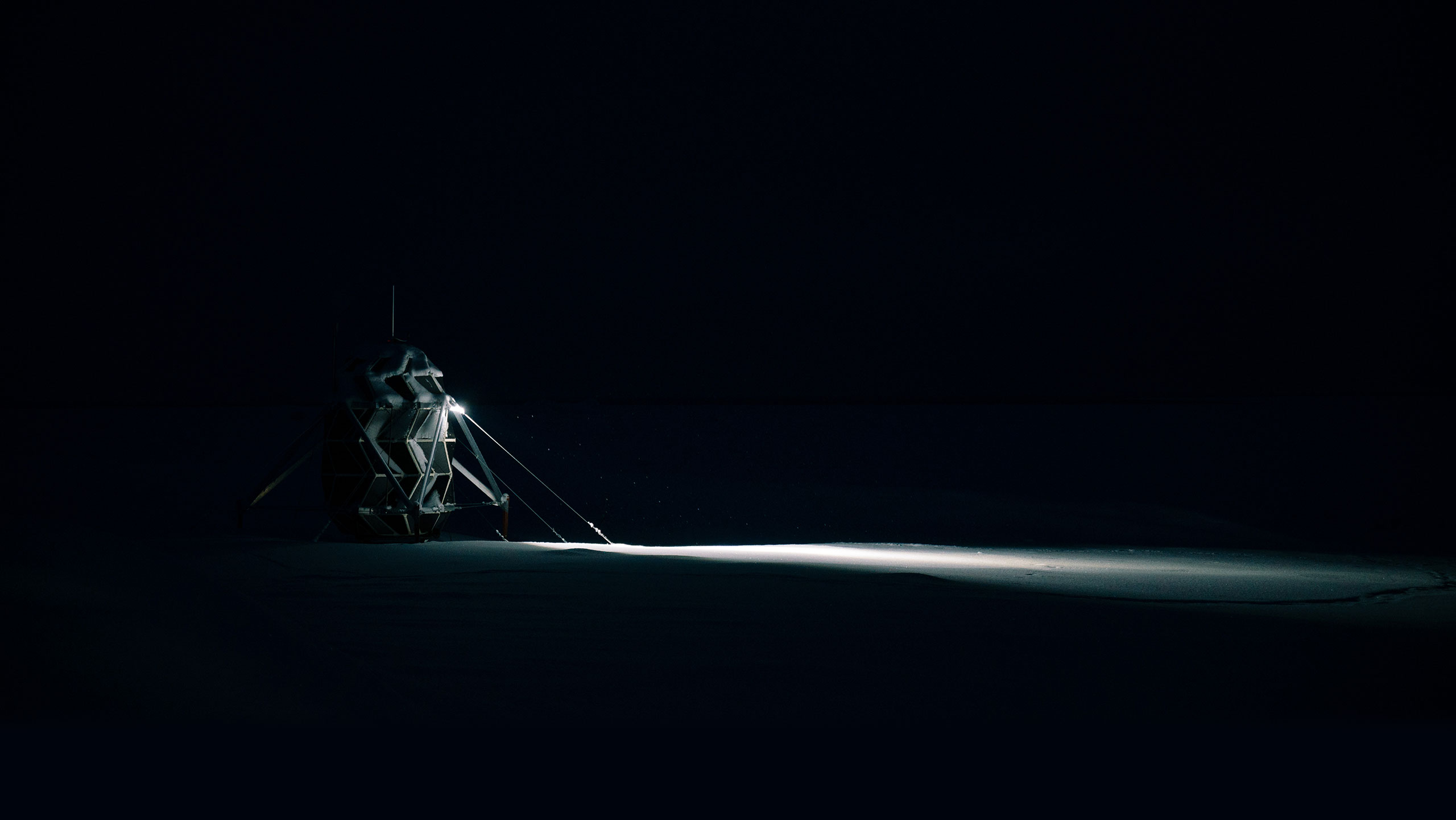

During the last 30 days of the expedition there was no sunlight, large flood lights attached around the top ring of the habitat made it easier to work and do maintenance outside.

FACTS

Arctic climate

Temperatures of -30°C and wind speeds of 90km/h, requires a sturdy habitat with great insulation.

Transportable

Shipping stuff to the Moon or Greenland is expensive. with a unique expanding design to save space during transport and maximize space after deployment.

Solar energy

The project simulates a mission to the peak of eternal light on the Moon, which has a similar day-night cycle to the Arctic day. We took full advantage of this by integrating solar panels on the exterior of the habitat and supplying it with as much energy as possible.

Polar Bears

On the Moon, there is a risk of being hit by a meteor. In Greenland, you might get “hit” by a polar bear. The habitat had to withstand a curious 650kg polar bear.

Zero Waste Ecosystem

The habitat had to leave no trace and recycle as much waste as possible.

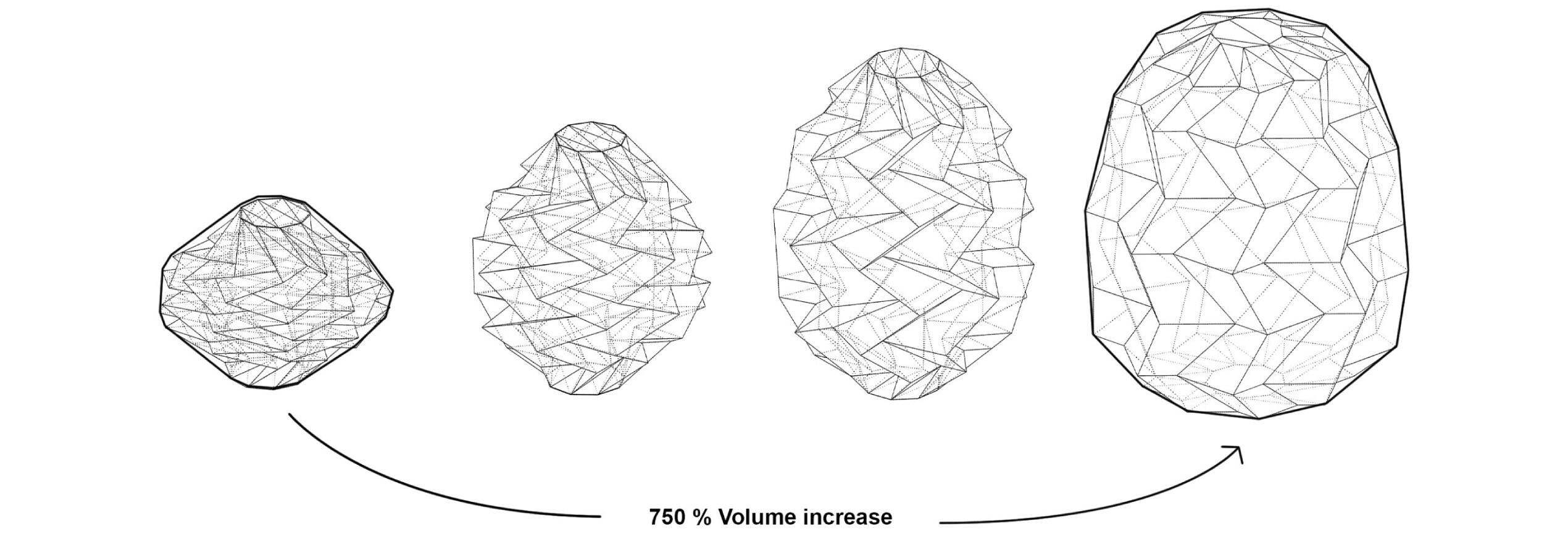

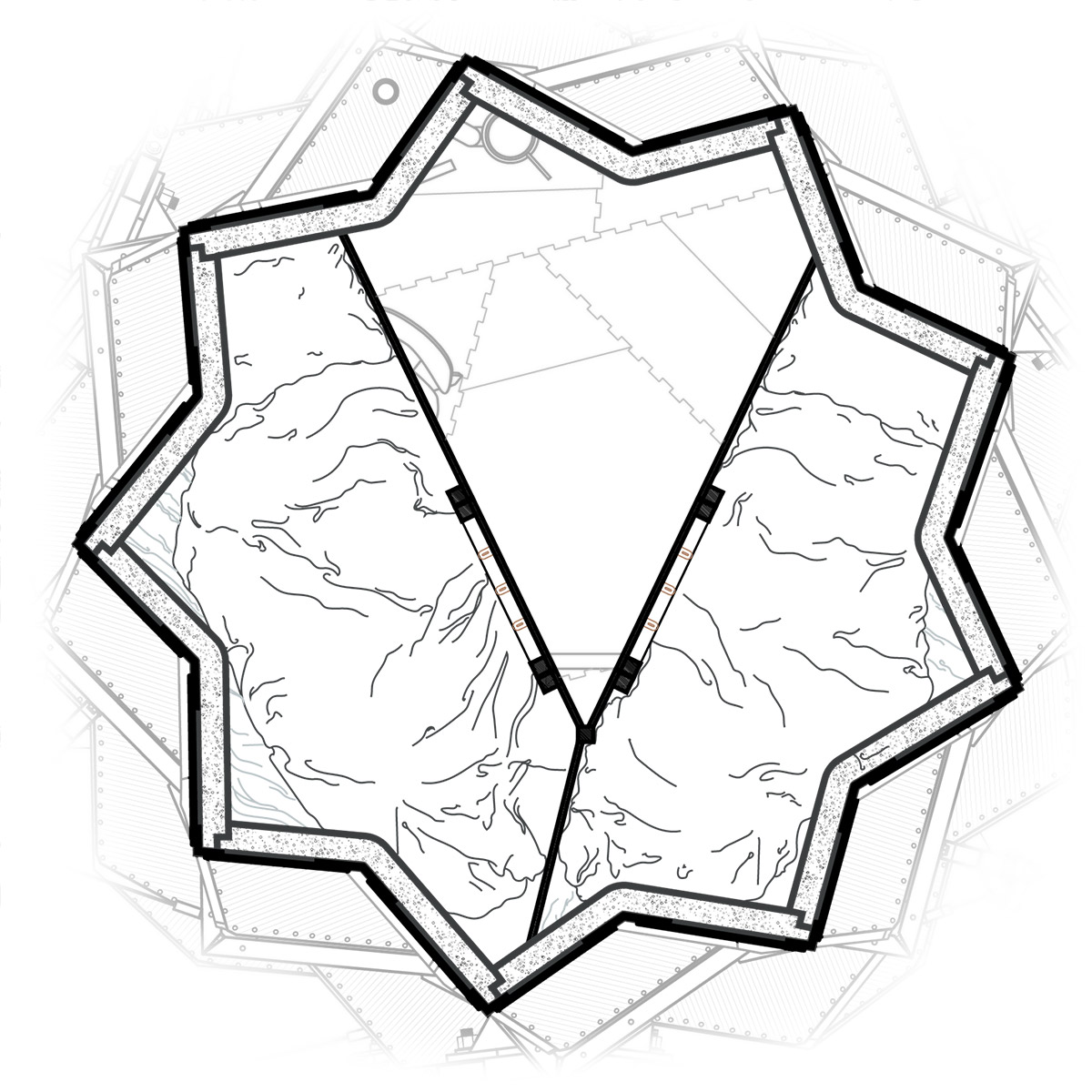

Deployable structure

One of the biggest challenges for the habitat is transportability both for Greenland and for a future Moon mission. By combining the ancient Japanese art of paper folding with the method of biomimicry we have come to a lightweight and strong foldable structure. The challenge lies in translating origami into thicker panels that can still fold. The answer may lie in nature. The final hinge design is a compliant mechanism; it’s lightweight, strong, airtight, simple to manufacture and to maintain.

It took the two simulation astronauts Karl-Johan and Sebastian 10 hours to deploy the shell in the arctic with no heavy machinery, using just their own physical output. The habitat grows in volume by 750% from compact to fully unfolded.

Container fit

For the Moon the habitat needs to fit within a rocket, but for the LUNARK mission it needed to fit within a shipping container and sustain the 5,500 km long ship journey to northern Greenland. A shipping container is significantly smaller than a rocket, measuring only 2.35m wide and 2.39m tall.

Origami development

We have investigated the 400-year-old japanese origami tradition. Origami is a special technique of folding paper which we previously explored conceptually in our award winning project: Circadian Lunar Home

In that project, we for the first time explored the theoretical possibility in using reinforced folding panels. The technique has previously been used for deploying solar panels, but the challenge lied in translating the origami from thin sheet to thicker panels following a double curved shell. Panels which can be insulated while still foldable. The photos show a process model of the folding habitat. The habitat expands 750% by volume, from compact to unfolded.

The habitat in -25 C during the expedition

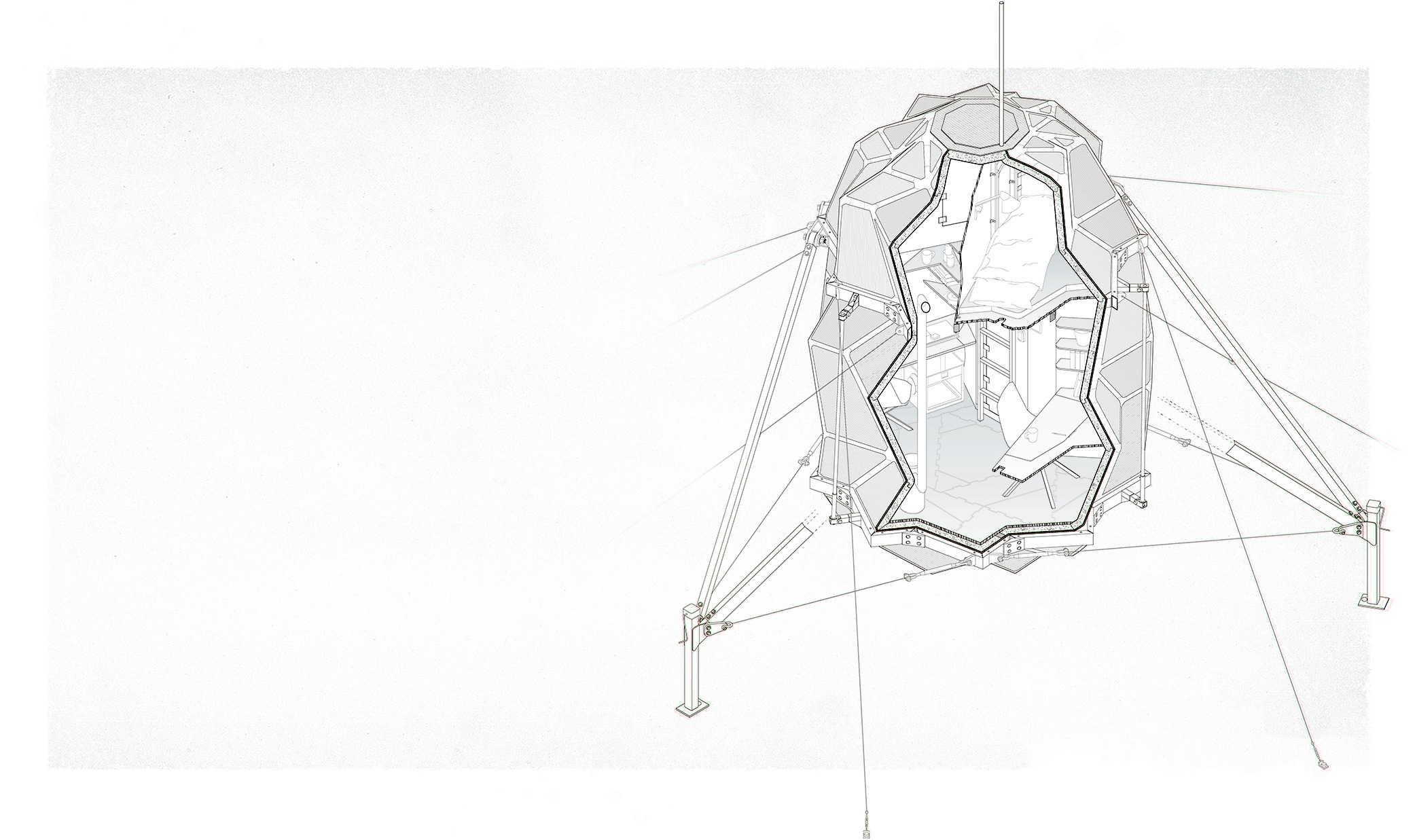

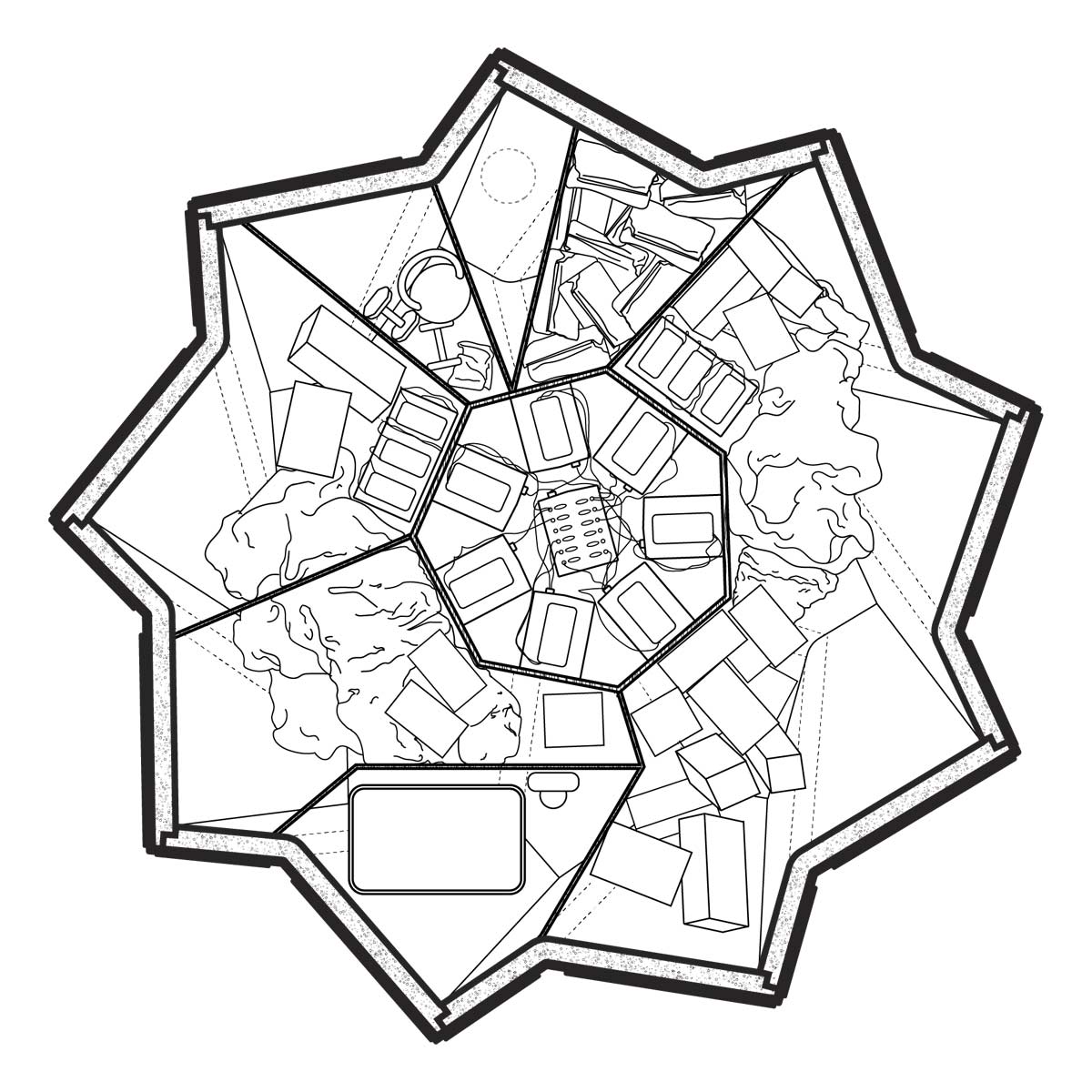

The habitat dissected

Here you can see an animated diagram of the structure and spatial organization of the habitat which Sebastian and Karl-Johan lived in for 3 months. It's an aluminium frame with interior separating walls which divide the space into airlock, crew cabins and living quarters. The whole exterior is covered with solar panels. The living quarters is where the crew exercised, worked, ate, talked, hung out, relaxed and everything else one does living.

Bottom Dome

- Personal storage #1

- Personal storage #2

- Food & consumables

- Workout equipment

- Urine Tank

- Power box with batteries, charge controllers, fuses, inverters and voltage adapters

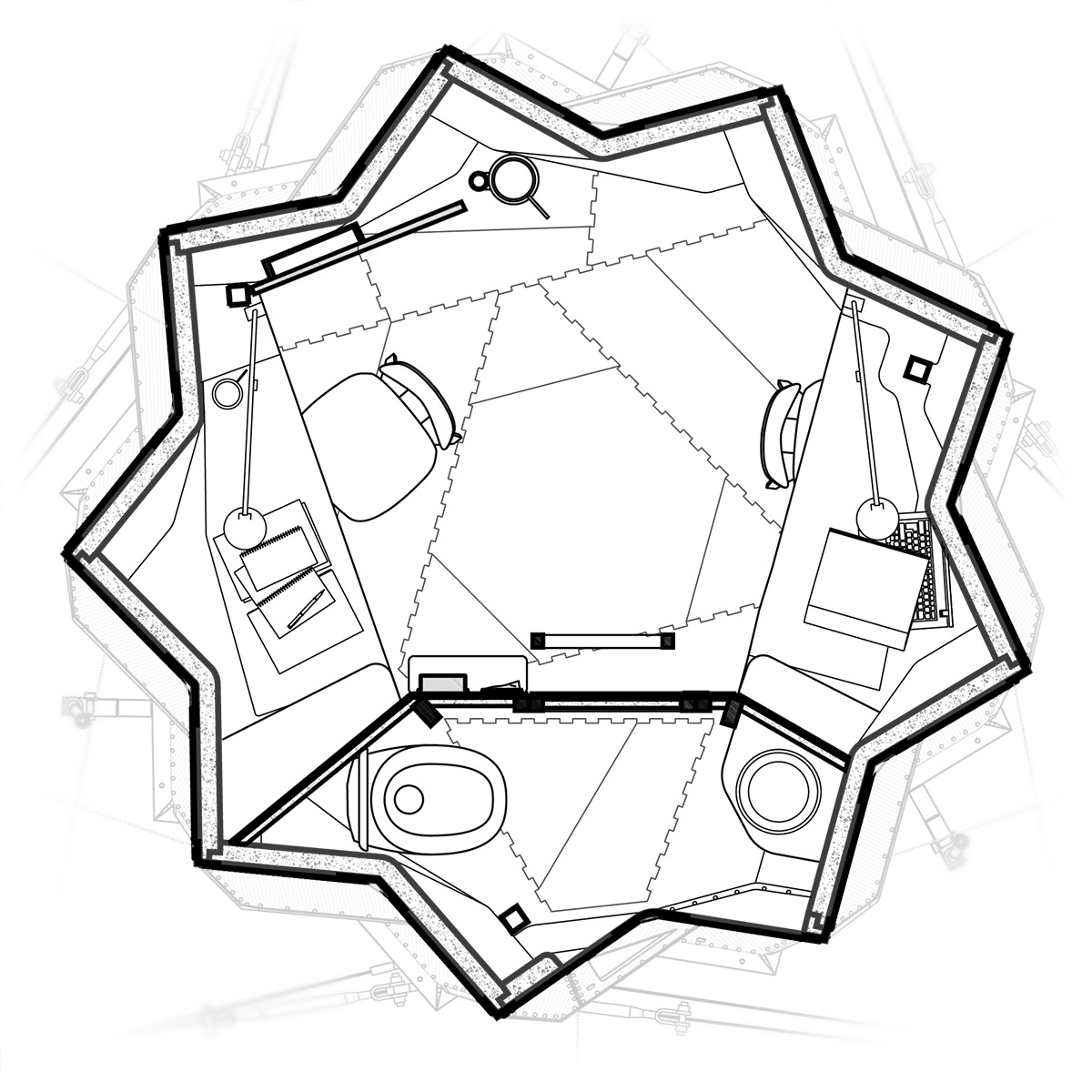

Middle cylinder

- Work desks

- Airlock

- Toilet

- Heater

- Algae reactor

- ODIN control center

- Storage/Airlock

Top Dome

- Sleeping pod #1

- Sleeping pod #2

- Circadian Light panels

- Pull-up bar

- Raven sensors

Even high above the arctic circle, the occasional bird would still visit

The interior

Well-being and indoor climate play a crucial role in our habitat architecture. The goal was to create a home rather than a survival machine. A space that felt safe, and stimulating for the entire duration of the expedition. The success-criteria was “create a space that sustained high functionality for a civilian crew with no training for extreme environments”.

We focused on tactile materials, and dynamic lighting and tried to avoid the sterile interior design of space stations which is the status quo.

The duration of space missions are increasing, therefore well-being only becomes more important for the astronaut's health and performance.

We don't have to go far away to find relevance for these studies. Most of us work indoors and we will spend a huge majority of our life inside. We strive to find healthy countermeasures for space and Earth. Our generation spends 90% of our time indoors. The expedition is helping to discover solutions in well-being and indoor climate on Earth as well as in space. The mission is a completely closed and confined living-space, perfect for a behavioral study.

Main room

The main living room, to the right is Sebastian's desk, to the left is Karl’s desk. In the middle is the ladder going up to the private sleeping cabins

Air-lock

The airlock’s main functionality is too keep the pressure or heat inside the habitat, it also doubled as toilet / wet room

Sleeping pods

The sleeping pod was the most private part of the habitat. The acoustically insulated dividing walls and the padded exterior walls provided a soft and safe envelope just large enough to fit a human being. It was important to give a sense of protection and safety.

Interior during "dusk" inside the habitat late one evening.

The construction process

Not only did we design the entire habitat, but we also built it completely from scratch in our facility in Copenhagen. With a large team of full-time employees and volunteers over a period of four months. It was tough work, and the raging corona epidemic made it a big logistical challenge. We did everything; cutting carbon fiber, gluing insulation, welding the frame, drilling the 5200 holes in the structuring, carving threads etc. and finally assembling everything in our workshop before packing it down in the container for shipping.